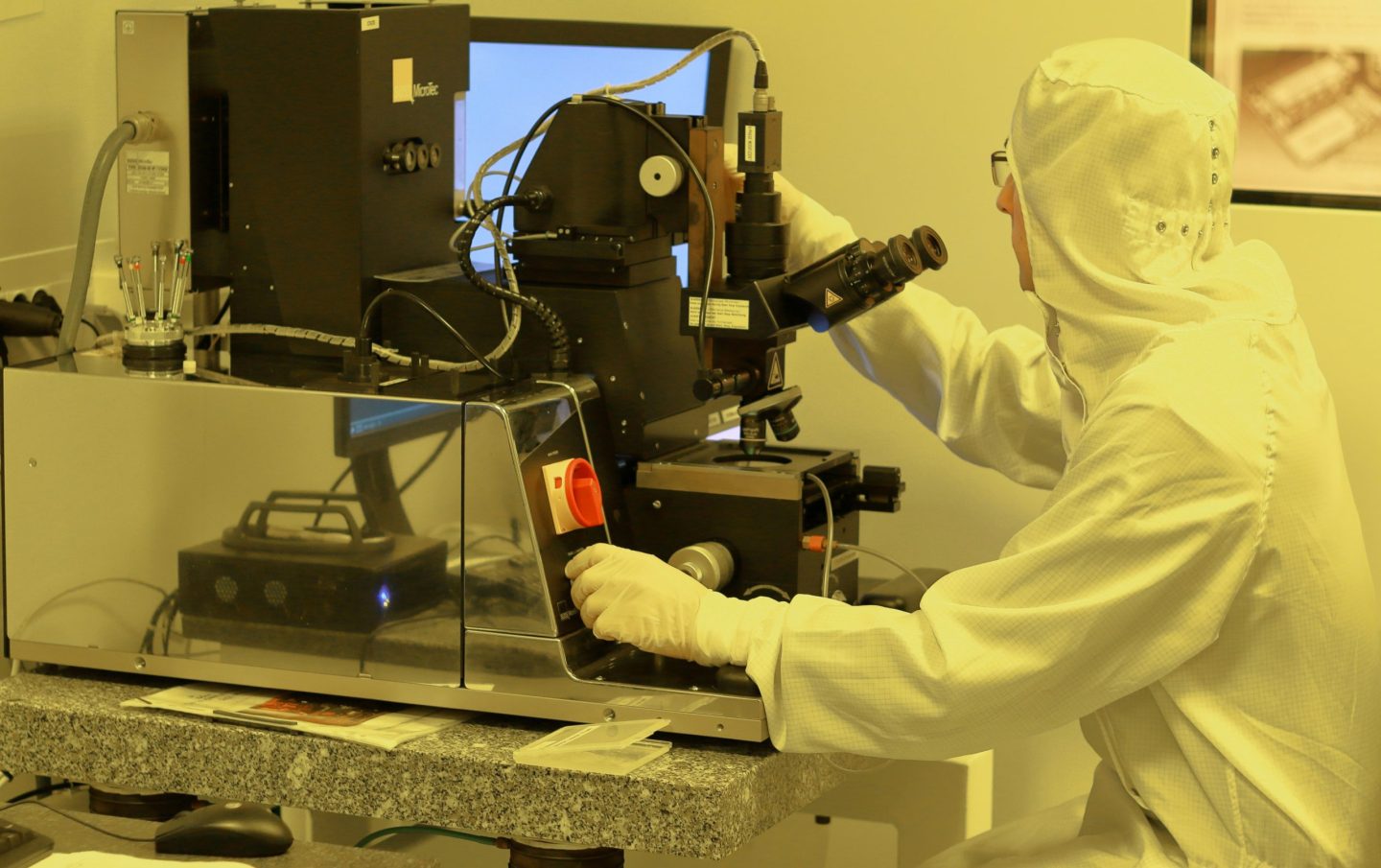

- Local equipment reuse offers a practical, low-impact way to make chips.

- Reusing chip-making tools cuts emissions and tackles rising e-waste.

Earth Day serves as a reminder that sustainability must be a shared responsibility – especially for industries shaping the digital age. The semiconductor sector is vital to power modern life, but its manufacturing footprint is growing, and the need for change is urgent.

Current trends suggest chip production emissions could rise to 168 million metric tons by 2050. E-waste is also climbing, hitting 62 million tonnes in 2022. As more equipment becomes outdated and discarded, the sector must embrace circular practices. This is where refurbishment may help – not only as a sustainable measure, but also as a business strategy.

In an interview, Kenneth Lee Wee Ching, CEO of Global TechSolutions (GTS), stated that sustainability in semiconductors isn’t a future aspiration – it’s a present-day necessity. In a recent conversation, he shared how refurbishment, localisation, and high engineering standards can change how the industry thinks about sustainability.

Localised production and emissions reduction go hand in hand

The global push to localise chip manufacturing is gaining pace. Governments and companies want resilient supply chains, but also cleaner, shorter logistics routes. Southeast Asia is becoming a strategic hub for fabs, and that shift brings sustainability opportunities.

“Localisation is reshaping how the industry operates,” Kenneth said. “It also brings new responsibilities.”

GTS operates refurbishment facilities in Singapore and Taiwan and is expanding into Malaysia. The cleanroom-certified sites give fabs quicker access to refurbished tools and parts, without relying on carbon-intensive global supply chains. By keeping operations regional, GTS shortens lead times, reduces emissions, and supports local industry needs.

“When localisation and sustainability are aligned, we create stronger, greener ecosystems,” Kenneth said.

Balancing innovation with responsibility

The chip sector is known for rapid innovation and companies are under pressure to increase output and performance. But this race comes with high environmental costs – more energy use, more raw materials, and more waste.

Kenneth believes that innovation shouldn’t come at the expense of responsibility. “The pressure to innovate can’t ignore the footprint it creates,” he said. “We help fabs stay efficient without increasing waste.”

GTS’s 25,000-square-foot facilities are equipped with Class 100 and Class 1000 cleanrooms. These are essential for front-end semiconductor refurbishment. Every refurbished tool is tested on platforms that match a fab’s specific configuration to ensure it’s ready for deployment.

“Our process is built for quality, speed, and sustainability,” he said. “When done right, refurbishment doesn’t delay progress – it accelerates it.”

Why refurbishment still faces resistance

Despite clear environmental and operational benefits, refurbishment is not yet standard practice in many fabs. Kenneth pointed to three main reasons: qualification delays, perception issues, and rigid procurement systems.

“Qualification cycles can take up to a year,” he explained. “That alone makes some fabs cautious.”

Many engineers still view refurbished parts as less reliable, especially if they’ve had bad experiences with general-purpose vendors. In addition, large manufacturers often have fixed supply chain protocols that don’t allow flexibility to consider alternative sources.

GTS addresses these concerns directly. Every refurbished item is cleaned and tested in high-grade environments and parts are evaluated under real fab conditions to ensure full compatibility. And GTS offers the same warranty coverage that’s provided with new components. “We don’t cut corners,” Kenneth said. “Reliability is non-negotiable.”

Tackling e-waste and equipment obsolescence

E-waste from electronics is growing fast, and semiconductor tools are part of the problem. High-value equipment is often discarded long before the end of its life, and such waste adds to environmental strain and raises costs.

Kenneth sees refurbishment as a solution to this overlooked problem. “There’s too much focus on chips alone,” he said. “The tools used to make them matter just as much.”

GTS extends the lifecycle of production equipment: Instead of replacing machines, fabs can restore them to full operational status, avoiding the need for new manufacturing, cutting carbon output, and reducing capital expenditure.

“Circularity isn’t just about reducing waste – it’s about keeping value in the system,” Kenneth said. “The less we discard, the less we have to extract.”

Proving performance, not just promising it

Sustainability is only viable if it doesn’t compromise output. That’s why GTS makes performance a priority. According to Kenneth, refurbished tools are engineered to meet the same performance benchmarks as brand-new ones.

“We back it up with data and warranties,” he said. Tools are tested under conditions that replicate a fab’s process environment. Uptime, consistency, and throughput are validated before deployment. That gives fabs confidence that they won’t face delays, breakdowns, or production issues.

“Environmental savings shouldn’t come with performance risk,” he said. “We make sure they don’t have to.”

What will it take to make refurbishment mainstream?

Right now, refurbishment is often treated as a fallback plan. But Kenneth argues it should be integrated from the start.

“Too many fabs only turn to refurbishment during a crisis,” he said. “By then, qualification timelines get in the way.”

He believes the shift will require both internal and external changes. Internally, fabs need to approve refurbishment as a primary sourcing option. Externally, the industry needs standards for measuring impact – like how much carbon or raw material a refurbished tool saves.

“Data helps drive adoption,” he said. “If you can show the savings, you can justify the decision.”

Government support could also help. Incentives like carbon credits, tax breaks, or government-backed reuse programmes would give fabs the push they need. “We’ve seen this work in other sectors,” Kenneth noted. “It’s time semiconductors caught up.”